400 Watt Metal Halide Lose 50% Light Output At About 50% Of The Life Of The Bulb...

How long a lamp lasts and how long it's good for are two totally different things. Most lamp manufacturers rate their 400WMH lamps between 16,000 and 20,000 hours.

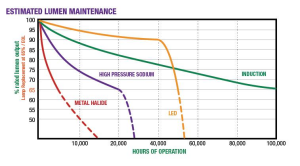

However as you can see from the chart below, the lamps are only producing around 50% of there intended light after only 10,000 hours. (IN FACT...If you look closely, the lighting output begins to decline after you turn on the power to the new bulb.)

So what does that give you? Well, you get a fixture that gives you the equivalent of 200 watts of light for the cost of 400.....pretty sweet deal isn't it? If you think so, you may want to look at the induction line below.

1000 Watt Metal Halide Lose 50% Even Faster...

Sadly, it doesn't get any better with a larger lamp....in fact its much worse.

1000WMH lamps are rated for a life of around 11,000 hours. So in keeping in the characteristics of metal halide they would produce the light output of a 400 WMH lamp in roughly 5,000 to 6,000 hours of use. This means that you are only getting 50% of the output from your 1000WMH, but you are still burning 1058 watts. You are getting 1/2 the light for 100% of the cost of operating the fixture. Is that a good deal? If you re lamped your facility it would take just over a year for you to be down to the light levels of a 400WMH lamp. The bad part is lamps and ballasts don't care if your not getting full light output, they will spin the meter just as fast on day 500 as they did on day 1.

The only real loser is the business owner footing the bill for electricity.

Can't You Just Replace the Bulbs More Often?

We have proposed upgraded lighting solutions to companies before and had them scoff at any numbers I have shown that consider payback in regards to maintenance savings.

Realistically with a metal halide that burns 12 hrs. per day you should be re lamping every 2 years, even if the lamp still works.

The reason being is that the lamp is only giving you 55%-60% of the light it's supposed to but your still paying for 100% of the light!

Let me put it this way. If our company came and installed 100 brand new lights at your business and within 2 years only 40 of them worked....would you feel ripped off?

Of course you would...and in reality the metal halide bulbs above your head IS ripping you off...it's doing the same thing! It is only working at 50% of its original output, yet your paying the same utility costs.